As greenhouse gas emissions from industrial activities continue to warm the planet, the stability and integrity of national electrical grids grows ever more concerning.

Time and again, power outages resulting from high demand and complications brought on by extreme weather events such as droughts, coastal flooding and prolonged heat waves continue to disrupt lives and take an ever-increasing financial toll.

Most electricity generation comes from burning fossil fuels — approximately 63.3 percent in 2019 — but this process releases greenhouse gases into the atmosphere which warm the planet and destabilize natural climate patterns, thereby increasing the number and intensity of extreme weather events.

And when there’s prolonged heat, the amount of electrical load placed on the grid dramatically increases from air-conditioning units.

The entire electrical system — which includes transportation networks for delivering fuel, power plants that generate electricity, and the transmission and distribution lines that funnel power to homes and businesses — was not designed to withstand many of today’s extreme weather conditions.

As extreme weather becomes more frequent and severe, the cost to fix grid-related damages soars. In the United States, the total cost of severe weather events shot from $20 billion per year in 1980 to $85 billion in 2010.

A combined total of 25 similar extreme weather events in 2011 and 2012 resulted in 1,100 fatalities and cost the nation $188 billion due to lost output and wages, spoiled inventory and restarting industrial operations. This year’s power outage in Texas brought a number of these issues to the forefront.

Israel’s electrical grid system has experienced similar disasters, particularly in the rainy winter months when severe windstorms knock out power across major cities.

As for electricity demand, Israel’s continued reliance on fossil fuels for electricity generation contributes to a growing financial and destructive burden.

“This is indeed something that we are seeing an increase in,” said Yacov Gorovoy, project manager at Israeli AI company Razor Labs. If the power consumption goes up, you need more infrastructure to support it, and it’s not always easy to make those necessary changes.”

The collaboration

Razor Labs is collaborating with Ohio-based Exacter on a predictive maintenance solution for electrical grid networks to prevent critical outages from occurring as frequently — saving billions of dollars annually.

Funding from the BIRD Foundation will enable the two companies to develop and commercialize mobile sensors that can identify deteriorated equipment and areas within electrical grids and draw connections to environmental factors that likely caused the problem.

Their efforts will effectively streamline the management of electrical grid operations so that every component across miles of the distribution grid can be monitored. In that way, potential power outages can be more consistently avoided, paving the way for a more robust grid network.

“Currently, it’s cost-prohibitive to monitor equipment conditions across the millions of miles of power lines in the U.S.,” said John Lauletta, CEO and CTO of Exacter.

“Our collaboration with Razor Labs will develop the next generation of mobile sensing devices that identify at-risk equipment and use machine learning and artificial intelligence to develop grid resilience forecasts. The system will correlate meteorological conditions, airborne contaminants and other environmental factors to forecast future issues.”

Prevent, react, or predict

When it comes to maintaining and monitoring power lines and electrical equipment, a utility company can either proactively send personnel out to inspect a particular component once every two months, for example, regardless of its condition, or reactively respond when the component breaks and needs to be replaced.

Preventive maintenance involves less downtime but incurs greater costs. Reactive maintenance is cheaper but usually involves more downtime.

The collaboration between Exacter and Razor Labs will offer a third option: predictive maintenance through AI and deep learning networks.

“The idea of predictive maintenance is that you can identify exactly when the need for maintenance would arise,” said Gorovoy.

“For example, if you have a power line, you can wait until the data shows signs of deterioration. And then, you can save time and effort by not having a routine inspection once every month or two. Instead, you can employ a data-driven inspection where the system can tell you to concentrate your maintenance efforts in a specific place at a specific time.”

This method saves time and effort because it lets grid operators know exactly where to direct their attention rather than taking the time to inspect the entire power line for the source of the issue. As a result, it leads to less electrical downtime in the event of a malfunction or avoids downtime altogether.

“In terms of preventing power outages, predictive maintenance — at least across the United States, for example — is a business valued at billions of dollars. Avoiding the cost of power outages, equipment failures, and the harm it causes businesses and private individuals is something that has tremendous value,” Gorovoy said.

How it all comes together

The grid-sensing technology is supplied by Exacter, while Razor Labs is providing the artificial intelligence and analytics portion of the project.

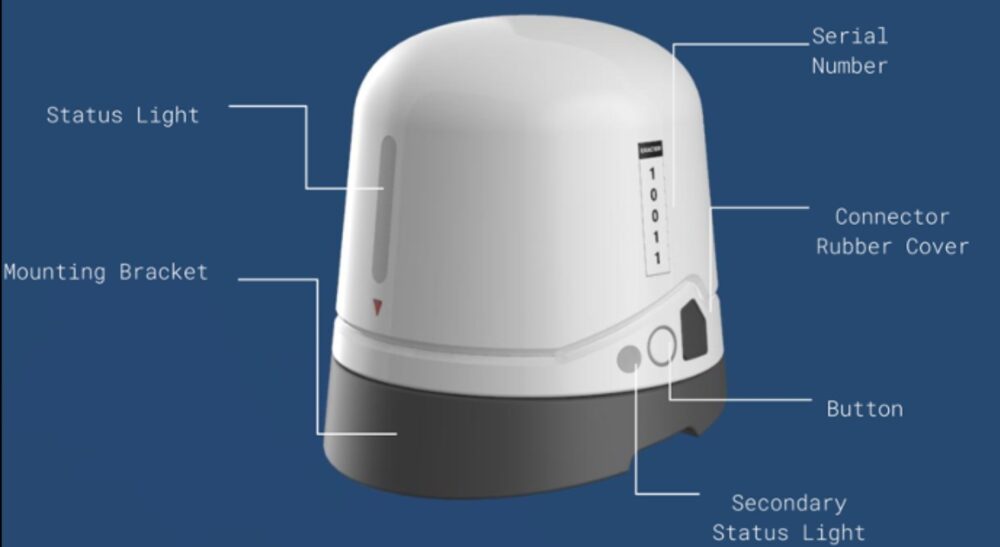

“When electric equipment deteriorates, it emits unique levels RF emissions from power lines and mostly from equipment on power lines such as transformers and insulators. The proprietary sensors that Exacter has developed can detect those RF frequencies,” said Gorovoy.

“After several passes, the sensors can identify areas with persistent readings and are able to determine the area exemplifying issues,” Gorovoy said.

“For this project, Exacter developed a second version of their proprietary sensor that’s capable of being installed on vehicles that they do not control. So instead of using their own vehicles, our joint project has a pilot right now in Akron, Ohio, where the sensors are placed on garbage trucks because they usually have a consistent route, and they provide full coverage within a certain window of time.”

At this point, Exacter personnel can interpret the data and determine the approximate source of the issue stemming from the power line or associated equipment. But the volume of data is quite large, so to expedite this process, the company needs Razor Labs’ expertise in deep machine learning and neural networks to interpret the data patterns more quickly.

“This is where we come in,” said Gorovoy. “Without any manual inputs, the sensor sends over the data through the cloud at the end of every day, and we perform analytics on it to create models that output the exact areas where malfunctions are going to happen and to understand the patterns that lead up to that.”

Even with the transition toward renewably generated electricity and the resiliency improvements it will impart to the current grid infrastructure, this predictive maintenance technology will still be highly valuable, according to Gorovoy.

“The collaborative project we are working on focuses on the power lines themselves and their degradation, so as long as electricity is provided via power lines, the solution would still be useful, regardless of how the electricity is produced.”

Is it coming to Israel?

The pilot project has an early 2022 deadline. After completion, the prediction system will be the property of Exacter.

While Razor Labs will receive the license for their data-driven technology and be able to suggest clients to adopt this system, Exacter will have the final decision on business strategy and deployment.

“We will be trying to bring this to Israel because it can significantly and positively influence life here by reducing power outages and helping the IEC [Israel Electric Corp.], but in the end it’s not us that decide on that,” said Gorovoy.

Considering that Razor Labs already has utility company clients in Australia and New Zealand and has a few projects in different areas with the Israel Electric Corp., Gorovoy remains optimistic about the project’s arrival in Israel.

“I know this is a very big priority for any utility company and for any utility regulator, so I’m assuming this would be something that will eventually come to Israel as well,” he said.

Predicting Electrical Grid Problems Before It’s Too Late first appeared on ZAVIT – Science and the Environment News Agency

The post Predicting Electrical Grid Problems Before It’s Too Late appeared first on Zenger News.